To each BMW enthusiast, we offer Online diagnostics for N43/N53 engines!

You are making screenshots using INPA and sending to us

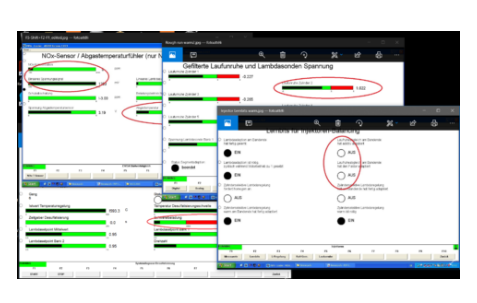

We inspect all information and send back initial report

If necessary further inspection will be requested

Round 2 we inspect received information and give recommendations

We provide assistance until all the problems are soloved

What does it mean?

We will evaluate live data of INPA, sent to us by you, if necessary – will give recommendations for deeper research, if it would be required.

What do you have to do?

Prepare the screenshots of the required menus from INPA and send them to us together with a description of the problem.

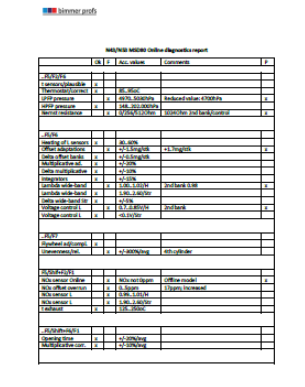

We will send the report as soon as possible with comments regarding incorrect or suspicious values, the report will be supplemented with images with marked incorrect values. We will give also suggestions and recommendations for required tests if the defect could not be recognized from the data sent.

We will help your car run smoothly again.

Following systems will be checked (initial report)

1. Basic data

Air consumption (air mass meter data)

The temperature of the engine, coolant, oil, plausibility of these data

The temperature of the exhaust system

HPFP and LPFP pressures

2. Lambda probes

Chemical activity

Heating parameters

Wide-band probes: proper Lambda readings

Control probes: the ability of voltage generation

3. NOx sensor

Proper data sending and status

Offset value

Wide-band and narrow-band Lambda data

4. NOx converter

Status: normal or damaged (from live data)

Amount of poisoning

5. Fuel mixture

Offset type adaptations: amount, the deviation between banks

Multiplicative type adaptations: amount, the deviation between banks

Additional adaptations for a cold engine

Lambda values and readings of Control probes (plausibility)

6. Injectors (data for each injector)

Actual parameters: offset and multiplicative data

Flow rate tests for low and high loads

Flow rate tests for the cold engine

Mechanical efficiency tests for Homogeneous injection (idle)

Mechanical efficiency tests for Stratified charge injection (idle)

Learnbits: status of completed/uncompleted adaptations

7. Analysis of error messages

Status (active/passive)

Importance and relationship with live data

Determination of damaged component (errors + live data)

Based on initial information, additional systems (if necessary) will be tested:

1. Check-up of fuel system: jittering of pressures, leakage, fuel distribution in the fuel tank;

2. Test of VANOS: offset adaptations, confirmed position, jittering;

3. Lambda probes: tolerance of parameters, current leakage;

4. EGR valve;

5. Crankcase valve;

6. Ignition system: misfire counters (ELM327 adapter required);

7. Generator; IBS; power management;

8. DISA valves;

9. Electric fan;

10. Engine cooling flaps;

11. Electric water pump;

12. Thermostat with electric management;

13. Oil pressure management;

14. Throttle and accelerator pedal; etc.

Example of Online diagnostics report