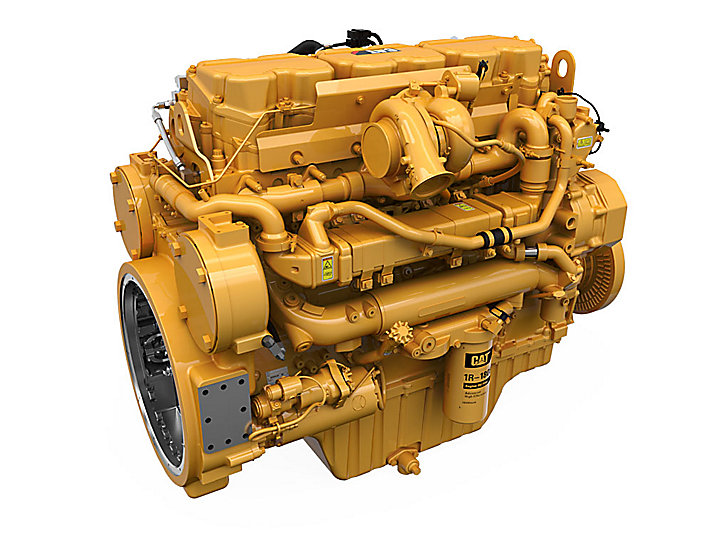

What is a Caterpillar ECM?

A Caterpillar ECM, or engine control module, is a small electronic unit that acts as the nervous system of your truck or equipment’s engine. The ECM provides split-second monitoring and data output for vehicle safety and functionality. It ensures that your CAT truck or equipment is operating at its most optimal performance. The ECM monitors several components such as a vast network of sensors and your emission control system. Caterpillar ECM modules come in a variety of shapes and sizes. Most applications are commonly referenced by the pin configuration for the connectors. Identifying the number of pins can help determine which application you have and can sometimes even determine the engine type and size. The most common pin configurations are 40-pin, 70-pin, and 120-pin applications.

Locating my Caterpillar ECM

Your Caterpillar ECM will always be located on the cool side of the engine. This makes a lot of sense considering the large amount of heat your engine produces. Engine temperatures can get upwards of 200 degrees Fahrenheit. This is not the ideal environment for electronic modules that serve a vital function for your engine’s performance. The control module is typically bolted to the side of the engine block using 4 mounting points. The Caterpillar ECM will also typically have 2 main engine harnesses running to the connectors. We recommend a certified technician assist with any removal or installation of your Caterpillar ECM.

Programming my Caterpillar ECM

Programming a Caterpillar ECM requires some very expensive programming and calibrating software. Caterpillar Software includes diagnostic capabilities and an extensive library of calibration files and parameters for each specific engine. These control modules are very complex and even though they might look the same, each module carries a unique set of features and settings. For example, two Caterpillar C15 ECM units with the same “6NZ” prefix and identical part numbers, will not interchange. It’s important to understand how critical programming and calibrating is for proper functionality and performance.

How Do I Know if my Caterpillar ECM is Bad?

Think of your Caterpillar ECM as a circuit board strapped to a scorching hot engine exposed to dirt, grease, oil, water, and heavy vibrations. These are the exact opposite conditions that these modules should be in for long-term optimal performance. No injector pulse and lost data activity are common symptoms of a faulty ECM. These faults are usually triggered due to component failure. Oil contamination and water damage are other common issues with ECM’s and these problems are typically visible and apparent. It’s worth noting that external faults can damage your Caterpillar ECM or any electrical module for that matter. Defective sensors and even a bad battery could cause electrical elements to overcompensate for the lack of power, thus creating inconsistent voltage spikes to your ECM. It’s very important if you or your mechanic suspect ECM failure, all potential external problems are diagnosed and repaired before installing your new or repaired ECM. If a bad sensor damaged your Caterpillar ECM and the sensor is still faulty, chances are it will damage your new ECM as well.

How to Clear ECM for Caterpillar Eninge Machine

Part I – Clearing ECM (TC Only)

1.ECM Clearing will only work on the following two types of ECMs with their corresponding suffix codes

• A4E2V1: JZ, LA, LC

• A4E4V2: JV, JW, JX, JY, LS, JL, JM

• A4E4V3 Suffix Codes: LF, LG, LH, LJ, LK, LL, LM, MC, MD, ME, MF, RA,RB, RC, RD, RE

Please note, that ECM Clearing is not allowed for ECMs programmed with On-Highway Engine software.

2.Ensure that a valid engine serial number is programmed into the ECM. The clearing process will not work without a valid programmed serial number. Navigate to Winflash,Click on Utilities, and choose “Clear ECM Memory”

3.ECM Clearing will only work on Non-Factory installed ECMs. If you are unsure if your ECM is factory installed, click “Yes” and verify in the FPS screen that appears.

Otherwise click “No” to continue with the ECM Clearing. You may also want to record the engine serial number and previously loaded flashfile in case of an issue during clearing.

4.Load the proper ECM Clearing file in Winflash and flash the ECM. Do not interrupt power during the clearing process or the ECM may become corrupted.

5.Return to Cat ET

6.The ECM Clearing Screen in Cat ET will appear. Click “Clear Memory” on the lower left hand side.

7.Click “Yes” to confirm and continue clearing.

8.You will then be prompted for a Factory Password. Follow your standard procedure for obtaining passwords.

9.Click “OK” to confirm that the ECM was cleared.

10.Disconnect from Cat ET. The ECM is now cleared and can be used for another application. A default interlock code of 43690 has been programmed into the ECM. Be sure to mark this ECM in some fashion to alert other users that this is a cleared ECM and will require additional setup.

Part II – Set Up Cleared ECM (TC or Technician)

11.In order to use this ECM for another application, you must reconnect to the ECM with Cat ET. When you reconnect, click the “Winflash” button.

12.Flash the new application software on the ECM in Winflash.

13.Once the flash completes, return to Cat ET.

14.The “Personality Module Mismatch” box appears. Click “Cancel” to continue setting up the ECM for the new application.

15.Navigate to the “Configuration” screen in Cat ET and program the correct “Engine

Serial Number” for the new application.

16.You must then disconnect and then reconnect to the ECM with Cat ET.

17.The “Personality Module Mismatch” box appears again. This time click “OK”.

18.Click “OK” on the next “Personality Module Mismatch” box that appears as well,after verifying the new engine serial number is displayed.

19.You will then be prompted for another Factory Password. Follow your standard procedure for obtaining passwords.

20.Once you have entered the Factory Password the process is complete. The ECM has now been successfully cleared, reflashed, and had the serial number reprogrammed to the appropriate new application.