The Cummins M11 series engine is known for its durability and reliability. However, there may come a time when you need to remove certain components like the hydraulic pump, sensor wiring harness, or internal actuator wiring harness for maintenance or repairs. In this article, we will guide you step-by-step on how to remove these components effectively.

2023.11 Doosan DMS-5 Data Monitoring System Diagnostic Software

Step 1: Disassembly of the Hydraulic Pump

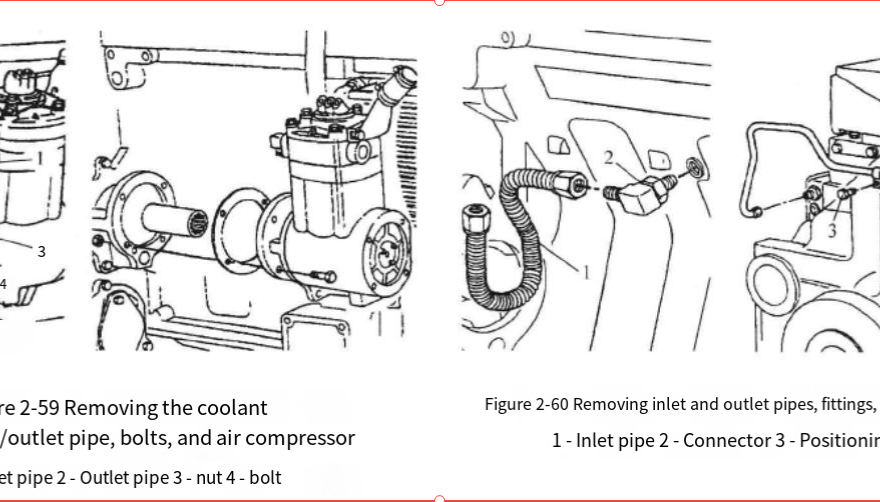

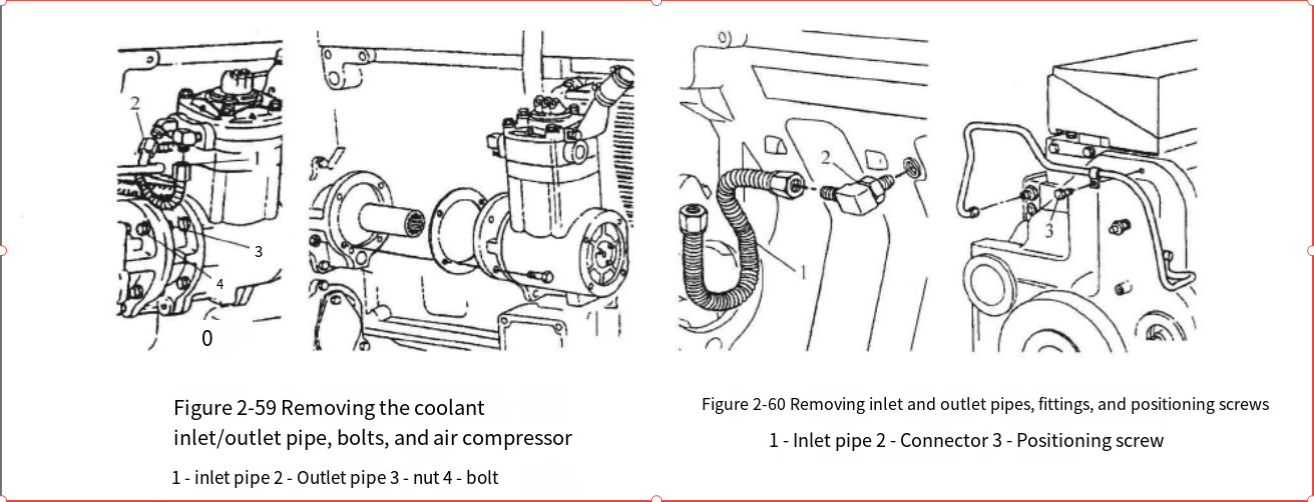

1. Locate and remove the two bolts securing the hydraulic pump and sealing gasket. Refer to Figure 2-61 for visual guidance.

2. Proceed to remove the three mounting bolts of the hydraulic pump drive device. Use a slide hammer and turning tool on the hydraulic pump drive adapter. For SAE “A” drive units, utilize two M10-1.50 ?0 bolts, and for SAE “B” type drive units, use two M12-1.75 ?0 bolts. See Figure 2-62 for reference.

3. Afterward, remove the hydraulic pump drive adapter, O-ring, and drive gear as shown in Figure 2-63.

Step 2: Disassembly of Sensor Wiring Harness and Internal Actuator Wiring Harness

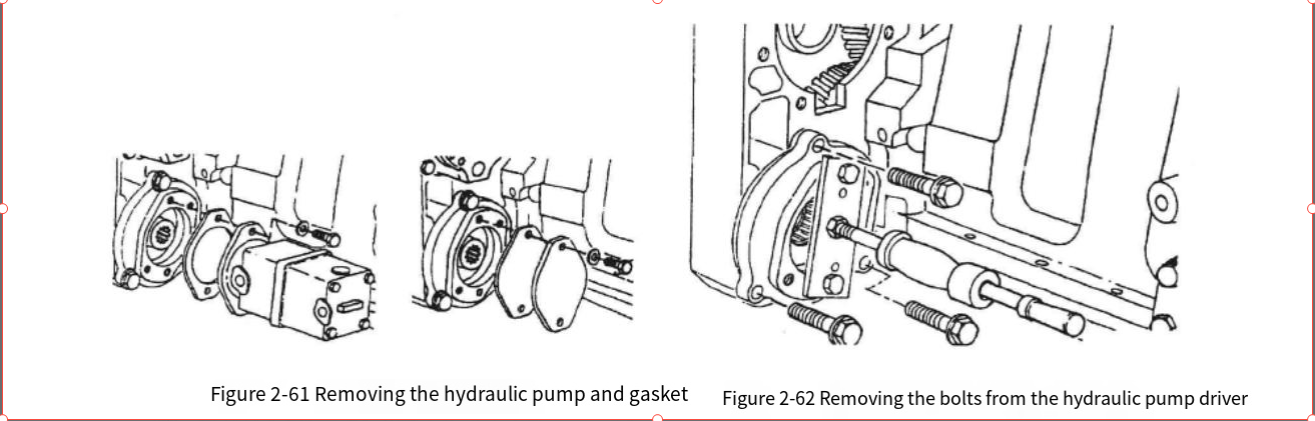

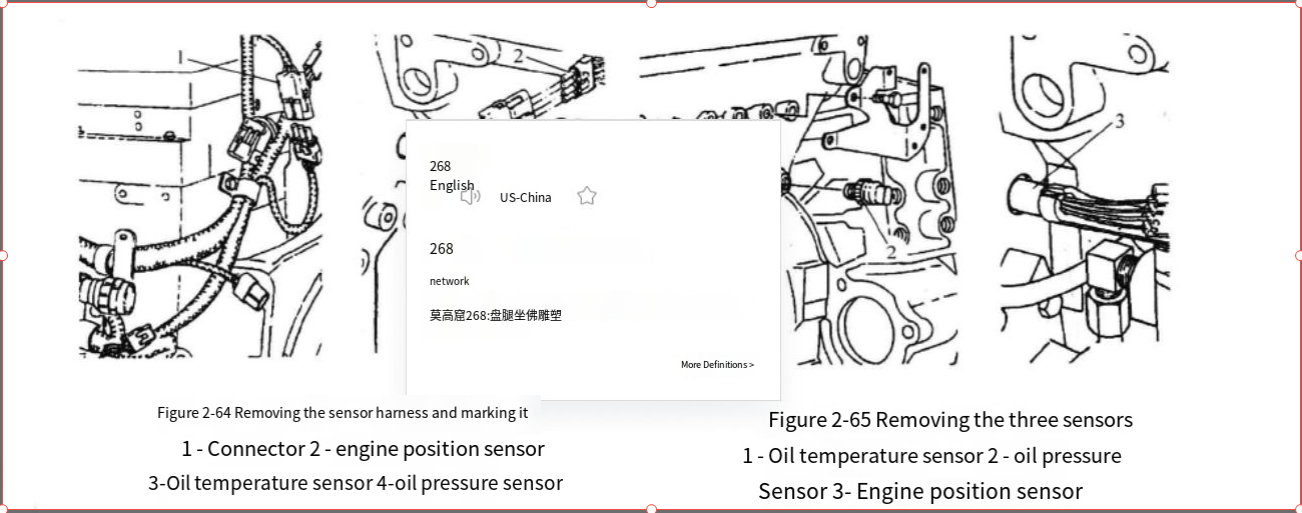

1. Begin by disconnecting and marking the sensor harness and actuator harness connectors. Refer to Figure 2-64 for visual assistance.

2. Remove the wiring harness bracket from the cylinder block and detach the oil temperature sensor, oil pressure sensor, and engine position sensor from the rear of the gear chamber housing. See Figure 2-65 for guidance.

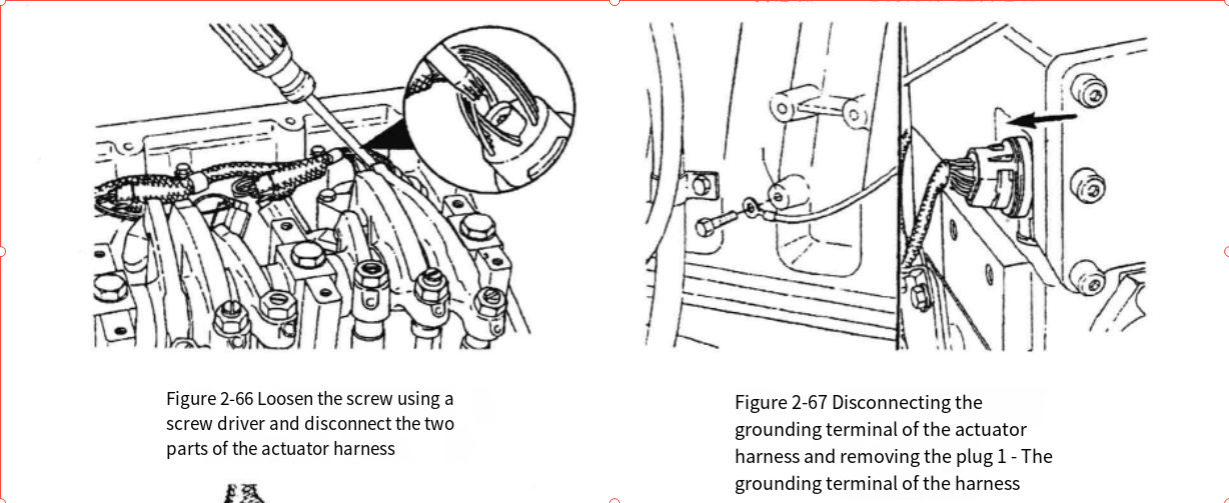

3. Loosen the actuator harness fixing screw at the rear of the rocker arm chamber housing using a Torx screwdriver (T25). Disconnect the two parts of the actuator harness as depicted in Figure 2-66.

4. Remove the actuator wire grounding terminal from the engine and unplug it from the rocker arm chamber housing. Refer to Figure 2-67 for clarity.

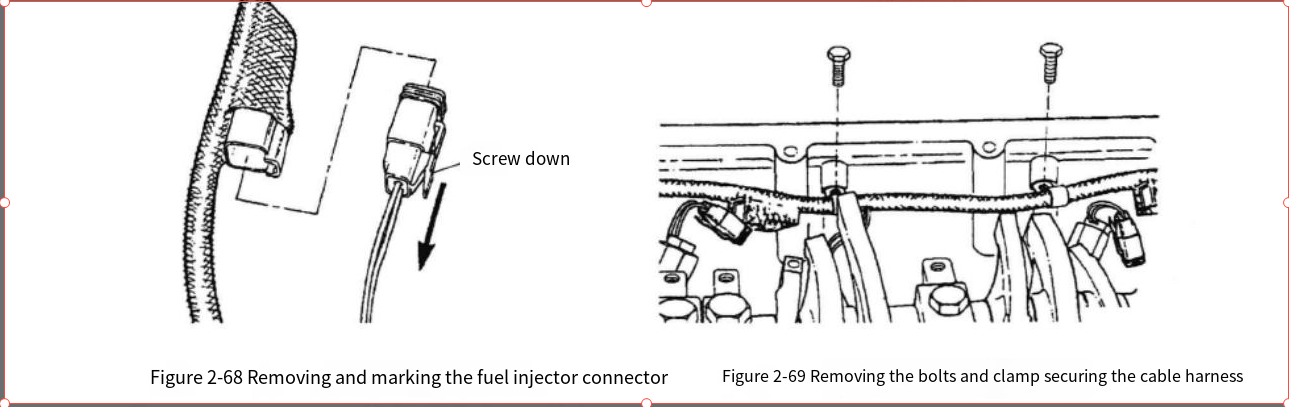

5. Disconnect the wire connector from the fuel injector, as shown in Figure 2-68. It is advisable to label the connectors to ensure easy reinstallation.

6. Remove the five bolts and clamps securing the wiring harness, as detailed in Figure 2-69.

7. Finally, remove a section of the actuator harness inside, as illustrated in Figure 2-70.

Conclusion:

By following the mentioned steps, you can successfully remove the hydraulic pump, sensor wiring harness, and internal actuator wiring harness from the Cummins M11 series engine. Remember to exercise caution and refer to the provided figures for better understanding. Proper disassembly plays a crucial role in efficient maintenance and repair of these components.