This guide explains how to drain and flush the engine coolant on a New Holland T9 Series tractor, ensuring your cooling system stays in top condition.

Related Contents:

2025 CNH EST 9.12 9.10 New Holland Diagnostic Software Free Download

CNH DPA5 Diagnostic Kit

CNH eTimGo 2025.04 Offline

Coolant Drain and Flush Procedure

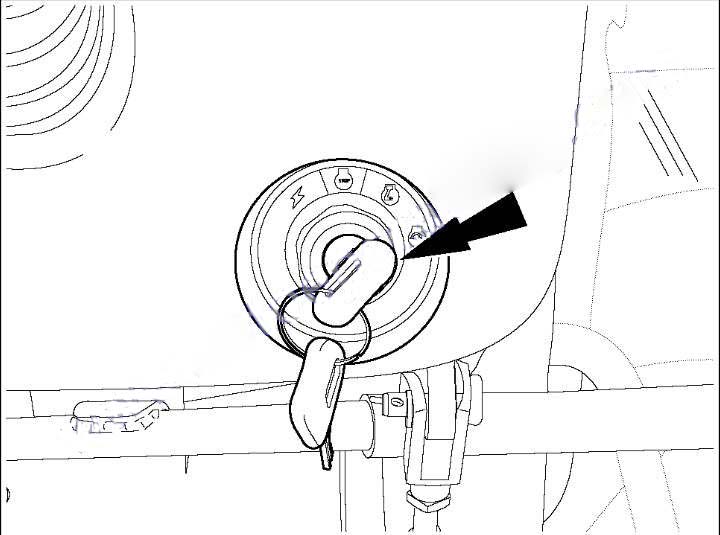

1. Park and Prepare

- Park the tractor on a level surface.

- Turn off the engine.

- Remove the key from the ignition switch.

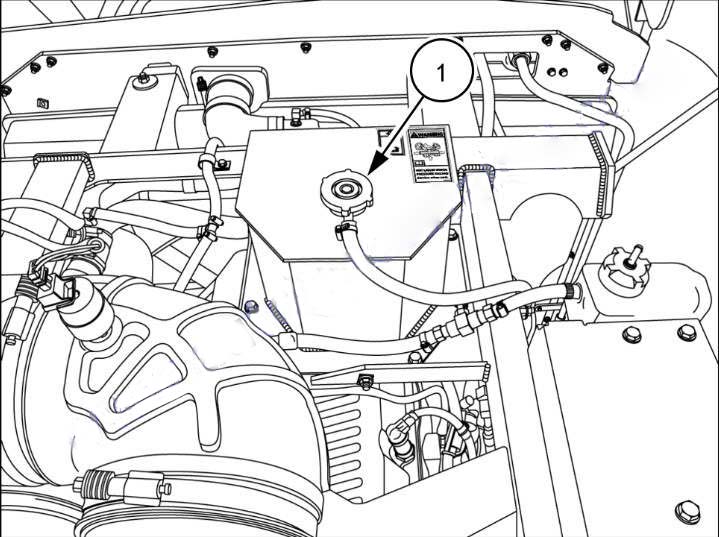

2. Release Cooling System Pressure

- Once the engine has fully cooled, carefully loosen the deaeration tank cap (1) to the first notch to release system pressure.

NOTICE:

The cooling system pressure cap includes a control valve that functions as a safety relief valve, maintaining system pressure.

Never run the engine without the pressure cap in place — doing so can cause system damage.

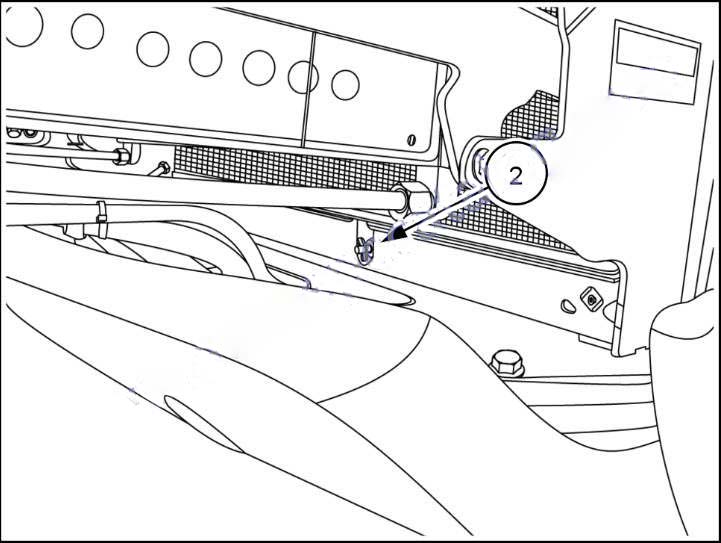

3. Drain the Coolant

- Open the radiator drain valve (2).

- Collect the drained coolant in a suitable container for safe disposal.

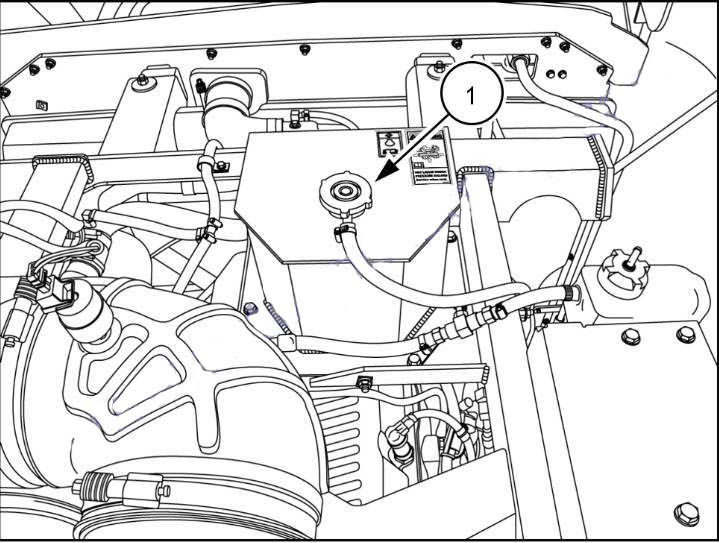

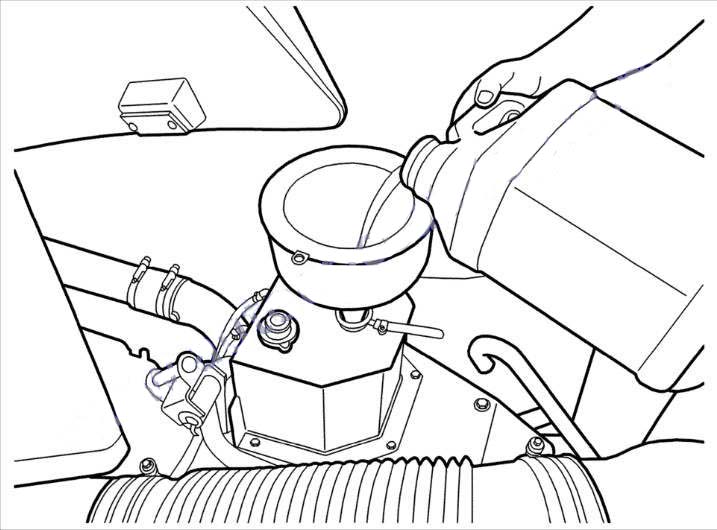

4. Add Radiator Cleaner

- Fully remove the deaeration tank cap (1).

- Pour in a commercial-grade radiator cleaner.

- Fill the system with clean water.

NOTICE:

Always follow the product instructions and ensure the cleaner is compatible with aluminum radiators.

5. Flush the System

- Drain out the radiator cleaner solution.

- Flush the entire system thoroughly with clean water, following the cleaner manufacturer’s directions.

6. Inspect Cooling System Components

- Check all hoses, fittings, and heater hoses for:

- Cracks or wear

- Loose connections

- Signs of leaks

7. Refill with Coolant

- Fill the cooling system with a 50/50 mixture of:

- AMBRA ACTIFULL™ OT EXTENDED LIFE COOLANT or

AKCELA ACTIFULL™ OT EXTENDED LIFE COOLANT

and distilled water.

- AMBRA ACTIFULL™ OT EXTENDED LIFE COOLANT or

- Fill to the fill neck of the deaeration tank.

8. Run Engine and Recheck Coolant Level

- Start the engine and let it run at low idle (1–2 minutes).

- Shut off the engine.

- Check the coolant level in the deaeration tank.

- If needed, top up to the fill neck and reinstall the pressure cap securely.

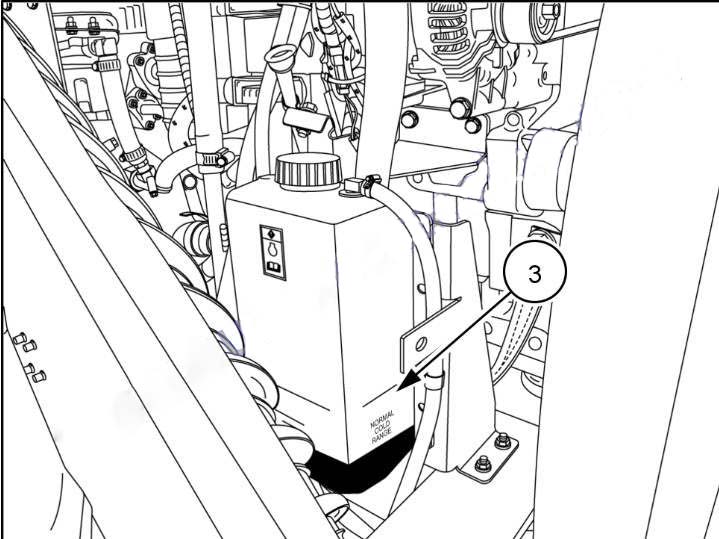

9. Fill Coolant Recovery Reservoir

- Fill the recovery reservoir (3) with the coolant mixture up to the full line.

- Reinstall the reservoir cap.

10. Bring Engine to Operating Temperature

- Start the engine again.

- Run it at 1200–1500 RPM until the coolant reaches normal operating temperature.

11. Inspect for Leaks

- Shut off the engine.

- Allow the system to cool completely.

- Carefully inspect the cooling system for any leaks.

12. Final Coolant Check

- Once the engine is cold, check the coolant level at the recovery reservoir only.

- Do not remove the deaeration tank cap at this point.

- If necessary, top off the recovery reservoir with the coolant mixture.

✅ Task Complete!

You’ve successfully drained, flushed, and refilled the coolant system on your New Holland T9 tractor, helping maintain optimal performance and prevent overheating issues.

If you want, I can format this into a printable checklist, visual guide, or step card — just let me know! Would that help?