Introduction:

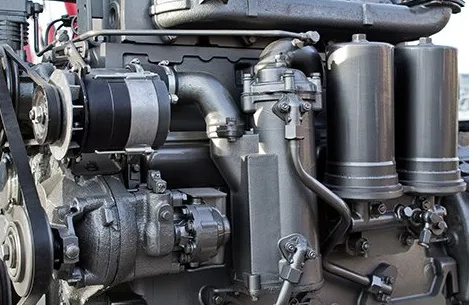

Diesel engines play a vital role in various industries, offering durability and power. However, similar to any mechanical system, diesel engines are susceptible to faults and failures during their lifespan. It is crucial to understand the common causes of these failures and how to effectively repair them. This article aims to shed light on the faults of diesel engines and provide practical solutions for their repair.

Causes of Diesel Engine Failures:

1. Mechanical Failure:

Diesel engine parts, such as pistons, valves, crankshafts, and connecting rods, can experience wear, deformation, or fractures over time. These mechanical failures can hinder the normal functioning of the engine.

2. Fuel System Failure:

Issues within the fuel system can significantly impact the engine’s performance. Common problems include fuel filter blockages, fuel injector failure, and fuel pump failure. Blockages in the fuel filter can result from the prolonged use of low-quality fuel or neglecting to replace the filter element. When fuel flow is obstructed, the engine may not receive an adequate fuel supply, leading to power loss or stalling. Similarly, faulty fuel injectors or fuel pumps can disrupt the proper fuel supply to the engine, affecting its overall performance.

3. Lubrication System Failure:

Insufficient oil, poor oil quality, or oil pump failure can compromise engine lubrication. Inadequate lubrication can lead to increased friction and wear, potentially causing severe engine damage.

4. Circuit System Failure:

Electrical faults within the circuit system can prevent the diesel engine from starting or running smoothly. Malfunctioning components like ignition coils or spark plugs should be promptly replaced or repaired.

5. Environmental Factors:

Environmental conditions, such as extreme weather, temperature, and humidity, can also impact the normal operation of diesel engines. Taking appropriate measures, such as insulation and adjusting operating parameters, is crucial to ensure engine performance under challenging environmental circumstances.

Solutions for Diesel Engine Faults:

1. Mechanical Failure Maintenance:

Inspect engine components regularly, including the crankshaft, connecting rod, piston, and valves. Promptly repair or replace any damaged parts. Implementing regular maintenance schedules and checks will ensure the engine’s normal operation.

2. Fuel System Maintenance:

Frequently clean fuel filters and injectors to ensure unimpeded fuel supply. It is vital to use a nano-filter for thorough cleaning. Replace faulty fuel pumps with high-quality alternatives and adjust fuel injection to ensure the correct fuel supply.

3. Lubrication System Maintenance:

Regularly check oil levels and choose high-quality oil for optimal lubrication. Replace faulty oil pumps promptly. Additionally, inspect and maintain other lubrication system components, such as the oil pan and oil filter, to ensure uninterrupted engine performance.

4. Circuit System Maintenance:

Ensure all circuit system components, including ignition coils and spark plugs, are functioning correctly. Replace or repair any faulty components promptly. Regularly check the battery power to guarantee a stable power supply.

5. Responding to Environmental Factors:

Implement appropriate protective measures, such as insulation enhancements and parameter adjustments, to mitigate the impact of adverse weather conditions on diesel engine performance.

Precautions during Diesel Engine Maintenance:

1. Prioritize safety by adhering to safety specifications to prevent accidents during maintenance operations.

2. Thoroughly read and understand the engine’s manual and operation instructions before conducting maintenance. Follow the correct maintenance steps and methods.

3. Select qualified products from reputable manufacturers when replacing parts to ensure maintenance quality.

4. Pay attention to the correct installation positions and directions of components during removal and installation processes.

5. Keep detailed maintenance records, including maintenance time, performed tasks, replaced parts, and other relevant information for future reference.

Conclusion:

Diesel engines are complex systems affected by various factors, including mechanical issues, fuel problems, lubrication system failures, circuit faults, and environmental conditions. Adhering to safety norms, following correct maintenance procedures, and using high-quality parts are essential for effective fault repair. By incorporating these solutions and maintaining comprehensive records, diesel engine owners can address common problems and maintain reliable engine performance. For further assistance or quality diesel engine parts, feel free to contact us.

More information about diesel diagnostic tools, please visit https://www.obd2tool.com